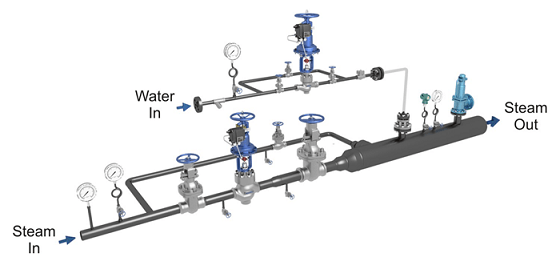

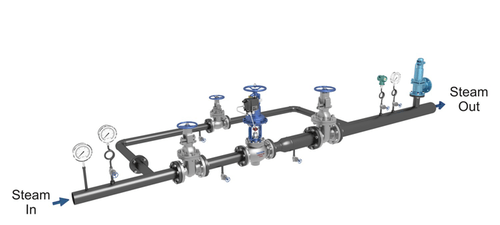

Steam Pressure Reducing and Desuperheating System

Steam PRDS is used for Steam Conditioning Services for reduction of pressure and temperature of steam. It is a combination of Control Valve for the pressure reduction purpose & atomizing nozzles, through which water is sprayed into steam for reducing the temperature. And spray water quantity required for the temperature reduction of the steam is controlled by separate spray water valve.

Accessories Pressure control system:

Pressure sensor, pressure transmitter, controller, I/P Converter, Pressure gauges, etc.

Accessories Temperature control system:

Temperature sensor, transmitter, controller, I/P Converter, Temperature gauges, etc.

Main Components of PRDSH:

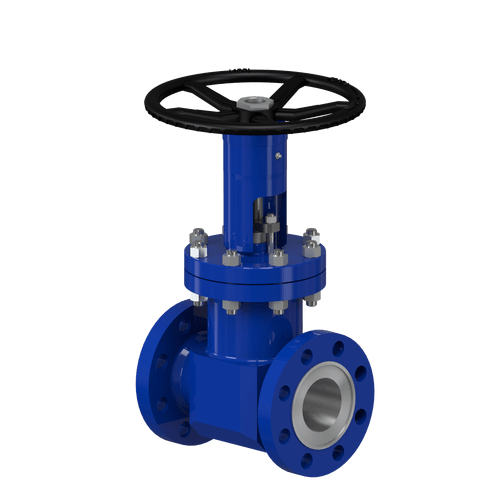

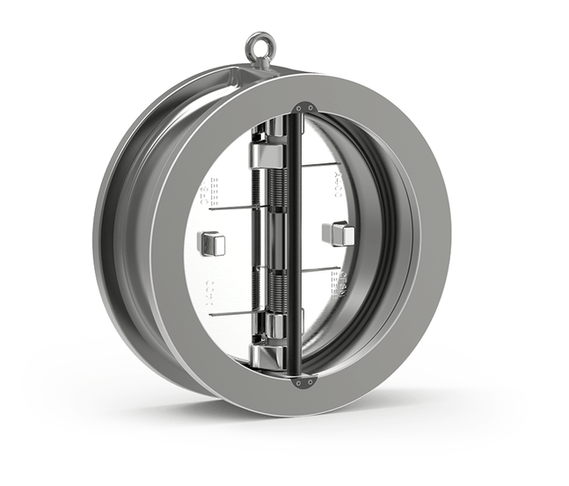

Pressure reducing valves, Isolation valve, Strainer, Bypass valve, Safety valve, Gauges, Instrumentation, Piping and fittings

Features of PRDSH:

- All stations are engineered and factory assembled

- Option of Self Regulating valve is also available.

- Stations are available in various sizes from 25mm upto 1000mm

- Pressure class available from ANSI 150# upto 2500#

- MOC: A106 Gr. B / A335 P11 / A335 P22 materials

- Most of the PRDS stations are supplied with ‘Combined PRDS’ valves which give the advantage of pressure reduction and temperature control in a single unit.

- If a Combined PRDS unit is not suitable; we offer separate PRV and DSH unit.

- Even with Combined PRDS valve, separate redundant Desuperheater can be included in case of bypass operation when main valve is under maintenance.

- The Water flow control valve and Waterline are also offered with the steam line, which ensures correct design and one to one matching of pressure and temperature control stations.

- It is designed inline with good steam engineering practices using our proprietary software.

- ‘KS Valves & Pumps’ manufactures most of the components of pressure reducing and desuperheating stations in-house which, enables quality control as per our standards.

- Various options and makes are available for isolation valve and bypass valves.

- We ensure availability of steam to the process of the right quantity, quality, pressure and temperature.

- For low sizes we maintain same pressure class at the inlet and outlet which allows high robustness and strength for the station. This ensures reliability of station even in case of any malfunction or failure.

- The entire assembly is hydro tested.

Desuperheater:

Steam DeSuperheater is used to spray water into steam, so that it gets mixed, resulting in reduction in the temperature at the outlet.

Type of DeSuperheater:

- Non-Integral type DeSuperheater: DeSuperheater nozzle and water valve are separate units.

- Integral type DeSuperheater: DeSuperheater is in-built with actuator, so that there is no need of separate spray water valve.

- Split PRDS: Separate PRV (Pressure Reducing Valve) and De-Superheater

- Combined PRDS: Both PRV and De-Superheater in a compact single unit

Combined PRDS helps to save the space and also cost of piping, as the unit is single and compact. For PRDS control system, there will be one Pressure loop and one temperature loop.