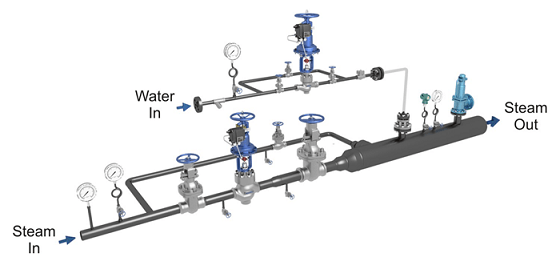

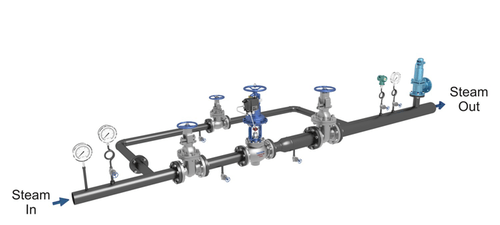

A good quality safety valve is essential in the unlikely event of overshoot in steam pressure.

‘KS VALVES & PUMPS’ safety valves are the most reliable and proven.

Mainly used to open at a predetermined pressure to protect vessel or system from excess pressure.

Inlet size range: DN 25 – DN 400

Outlet size range: DN 50 – DN 450

Pressure Class: 150 LB – 2500 LB

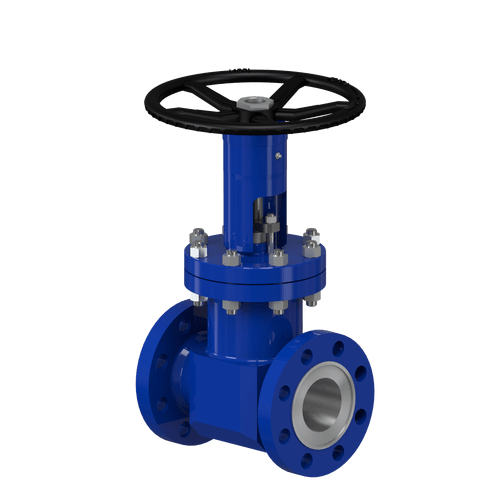

Make- KSV

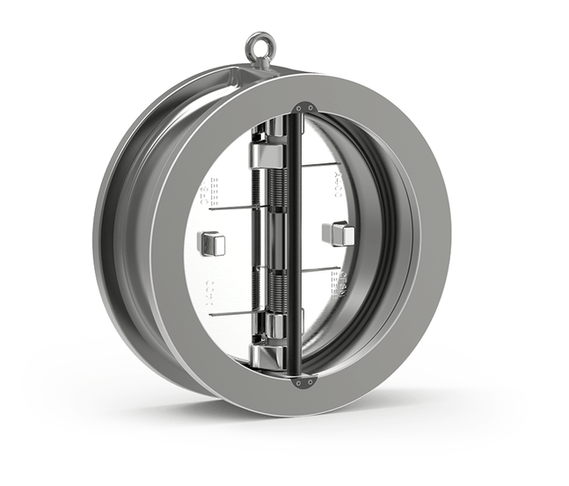

Structure- Open bonnet & closed bonnet

Balanced type- Balance bellows, Balance piston, Balanced bellows & piston

Bellows material- AISI 316L, AISI 304L

Ends- Flange ends (ASME B16.5)

MOC Body - Stainless steel 316L/304L, SS316/304, SA 216 WCB

Seat- Soft seat(Viton, NBR etc), Metal seat (Stellited)

O-Ring- NBR/Viton/PTFE

Spring MOC- Hast-alloy B&C, Inconel, DIN 17223, AISI 302, AISI 420

Manufacturing std- API 526, API 520 and API 521 , IBR

Testing std- API 527

Advantage- 100% compatibility to API 526, Adjustable blow down, Versatile for many services

Sector- Oil & Gas, Chemical Industry, Energy Sector, Petro-chemical Industries

Application- Steam services, air, vapour & gas services also

Special- IBR, Fully stellite trim (Trim 5), Pilot operated safety valves ( On request), Supplementary loaded valve (on request), Conventional design (Steam line)