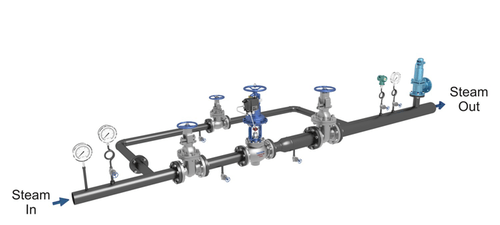

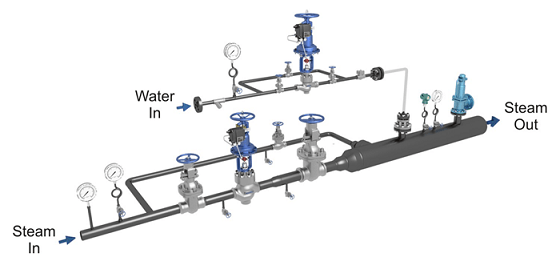

The KSVP pressure reducing station is an engineered and factory assembled unit. It is designed in line with good steam engineering practices using our proprietary software. We KSVP manufactures all the components of the pressure reducing station in-house, which enables quality control for each component to highest standards. Every component is tested on live steam & the entire assembly is hydro tested.

Steam should be available to the process in the right quantity, should be of the right quality and should be at the right pressure and temperature.

Reducing Valve

The reducing valve should be selected to ensure that the right quantity of steam, at the right pressure, is available to the process consistently. The turndown is an important parameter to be selected. We, with our wide range of pressure reducing valves are fully equipped to select the right valve for your needs.

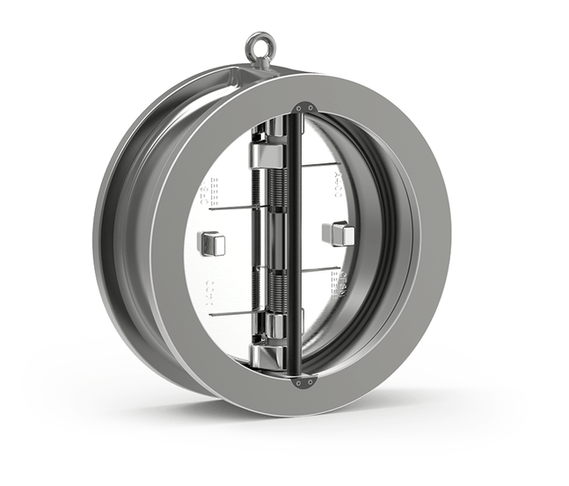

Moisture Separator & Strainer

Clean dry steam is necessary for achieving maximum process efficiency with minimum wastage of steam. The baffle design moisture separator is designed for high separation efficiency. Clean and dry steam also prevents pitting and erosion of the valve trim and seat.

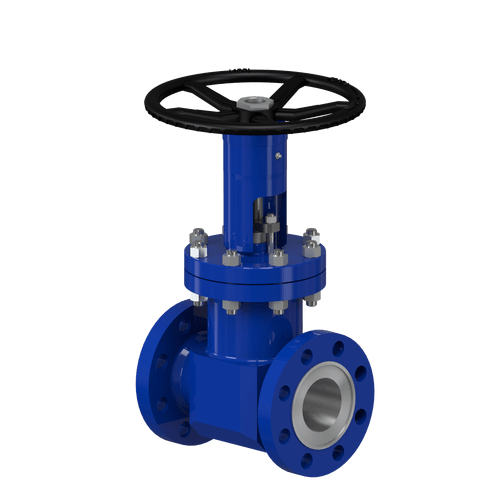

Isolation Valves

Zero leak piston valves prevent losses through the gland as well as prevent any inline leakage. Our piston valves confirm to leakage class VI, guaranteed zero gland leakage, are scrap-free design, can be maintained inline and last a lifetime.

Safety Valve

Used to protect the system with excessive lines steam pressure.